How to Inoculate Grain Spawn: A Step-by-Step Guide

- Harold Evans

- Feb 7, 2025

- 5 min read

Updated: 1 day ago

Inoculating grain spawn is one of the most critical steps in mushroom cultivation. It’s the process of introducing mushroom mycelium to sterilized grain, allowing it to colonize and prepare for fruiting. Whether you’re using liquid culture (LC) or an agar wedge, the right techniques can mean the difference between a thriving grow and contamination issues. This guide will walk you through each step, ensuring a smooth and successful inoculation process.

Understanding Grain Spawn and Its Role

Grain spawn serves as the intermediary step between spore or culture expansion and bulk substrate colonization. Properly inoculated grain results in robust mycelial growth, reducing colonization time and minimizing contamination risks.

Most cultivators opt for oats, wheat, rye berries, or millet as grain spawn due to their high nutrient content and water retention properties. Ensuring your grain is fully sterilized before inoculation is essential for preventing unwanted bacterial or mold growth.

What You’ll Need

Pre-Sterilized Grain: Prepared in jars or bags, ready for inoculation. If preparing your own jars, quality injection port lids make inoculation cleaner and reduce contamination risk compared to traditional filter patch lids.

Liquid Culture (LC) or Agar Wedge: Use a sterile syringe for LC or a clean, colonized agar plate for wedges.

Clean Workspace: A still air box (SAB) or laminar flow hood minimizes airborne contaminants.

Sterile Tools: Alcohol wipes, a flame source (such as a butane torch), a sterile syringe for LC, or a sterile scalpel for agar wedges.

Step 1: Preparing for Inoculation

A clean and sterile environment is essential for reducing contamination risks. Before beginning, eliminate any unnecessary airflow in the room. Turn off fans, air conditioners, and heaters to prevent airborne particulates from settling into your workspace.

Sanitizing Your Workspace

Wipe down all surfaces, tools, and containers with 70% isopropyl alcohol.

If using a still air box, mist the interior with a fine spray of water mixed with a drop of dish soap to help trap airborne contaminants.

Wear gloves and a face mask to further minimize contamination risks.

By setting up a controlled environment, you create the best possible conditions for successful grain spawn inoculation.

Step 2: Inoculating the Grain

The method of inoculation depends on whether you’re using liquid culture (LC) or an agar wedge. Each technique has its advantages, but sterility is key in both cases.

Using Liquid Culture (LC):

Disinfect the injection port with an alcohol wipe. Self-healing injection ports allow multiple inoculations without breaking the sterile seal—a significant advantage over basic filter lids.

Flame sterilize the syringe needle until red-hot. Allow it to cool briefly without touching any surfaces.

Insert the needle into the injection port and inject 1-2 cc of liquid culture into the grain jar. Avoid over-injecting, as excess moisture can lead to bacterial contamination.

If using grain bags, gently massage the bag to distribute the liquid culture evenly without compacting the grain.

Using an Agar Wedge:

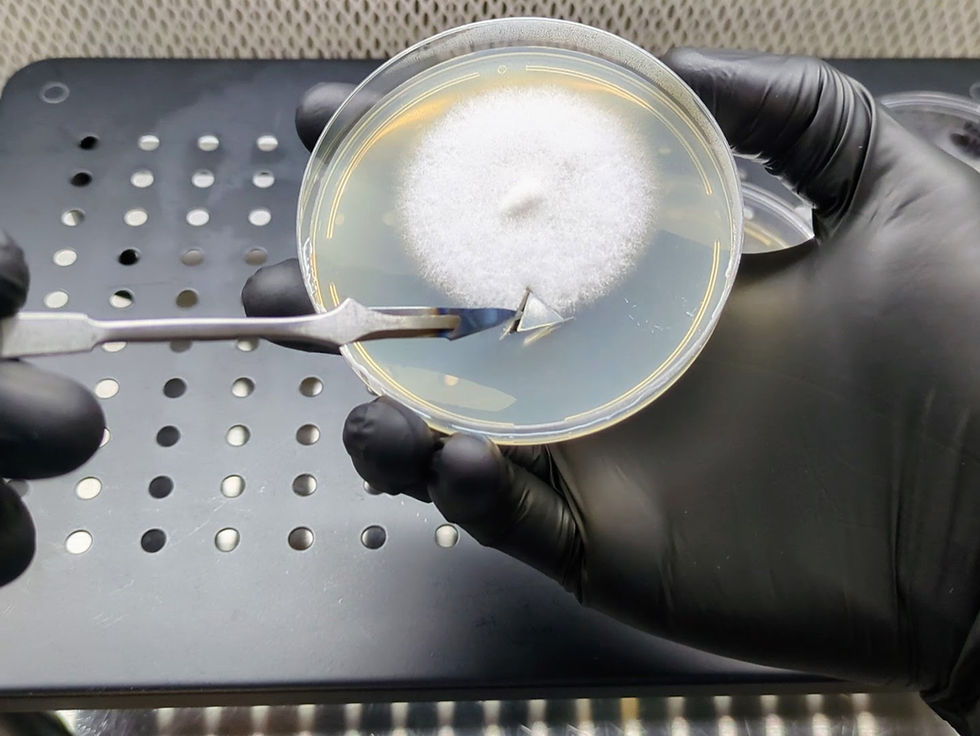

In your sterile workspace, use a scalpel to cut a small wedge from a fully colonized agar plate.

Carefully open the grain jar or bag, minimizing exposure to open air.

Drop the agar wedge onto the grain and immediately reseal the container.

Gently shake the jar or mix the bag to ensure the agar makes good contact with the grain.

Important: Avoid using spores directly to inoculate grain spawn, as they carry a higher risk of contamination. Instead, grow out spores on an agar plate first to ensure a clean culture.

Step 3: Incubating the Inoculated Grain

Once inoculated, the grain needs to be kept in an incubation-friendly environment for colonization to occur.

Ideal Incubation Conditions:

Temperature: Keep grain spawn at 68-72°F (20-22°C) for optimal growth.

No Direct Heat Sources: Avoid storing grain jars near radiators, direct sunlight, or heat mats, as excessive heat can dry out or kill mycelium.

Monitor for signs of colonization, which typically appears within 5-10 days as white, cotton-like mycelium begins spreading throughout the grain. Liquid culture (LC) generally colonizes faster than agar wedges due to its ability to disperse evenly throughout the grain, providing multiple points of contact for the mycelium to expand from, whereas agar wedges must first establish before spreading.

Step 4: Shaking at 30% Colonization

At around 30% colonization, when mycelium has spread through a third of the grain, it’s time to shake the jar or bag. This helps distribute colonized grains among uncolonized grains, significantly speeding up the colonization process.

Gently shake the jar to break up and evenly distribute mycelium-covered grains.

For grain bags, thoroughly mix the grain to ensure even distribution of mycelium, taking care not to overly compact the substrate.

After shaking, expect to see the mycelium recover within 24-48 hours—a good sign of healthy growth.

Step 5: Reaching Full Colonization

Complete colonization usually takes 2-4 weeks, depending on the species and environmental conditions.

At 100% colonization, the grain should be fully covered in thick white mycelium.

Before using, perform a final shake to test recovery—healthy mycelium should bounce back within 24-48 hours.

Discard any jars or bags showing signs of contamination, such as odd colors (green, black, or orange) or foul odors. Healthy mycelium typically has a signature earthy, mushroom-like scent—any deviation, such as a sour or overly sweet smell, may indicate bacterial contamination.

Step 6: Using Your Fully Colonized Grain Spawn

Your fully colonized grain spawn is now ready to be introduced to a bulk substrate such as coir, hardwood sawdust, or manure, depending on the mushroom species being cultivated. At this stage, the grain acts as an inoculant, spreading its mycelium into the new substrate to prepare for fruiting.

Tips for a Successful Inoculation Process

Work Sterile: Keeping tools, workspace, and hands as clean as possible prevents contamination.

Use Reliable Equipment: Quality lids with durable injection ports and proper gas exchange prevent both contamination and stalled colonization from poor airflow.

Spot Contamination Early: Any discoloration, foul odors, or abnormal textures indicate contamination. Discard immediately.

Move Slowly: Quick movements in a still air box can create airflow, increasing contamination risks.

Avoid Overhydration: Excess moisture in grain can cause bacterial bloom and inhibit mycelial growth.

By following these detailed steps, you ensure that your grain spawn develops strong, uncontaminated mycelium, setting the foundation for successful fruiting and abundant mushroom harvests.

Final Thoughts

Mastering grain spawn inoculation takes practice, but with experience, your process will become second nature. By refining your technique, maintaining strict sterility, and controlling environmental factors, you can achieve consistent success in your mushroom cultivation efforts.

Ready to Streamline Your Grain Spawn Process?

Whether you're preparing your own jars or starting with pre-sterilized grain, having the right equipment makes all the difference.

Premium Grain Jar Lids (6-Pack) - Autoclavable PP5 construction with self-healing injection ports and silicone-sealed gas exchange. Built for reliability and repeated use.

2lb Sterilized Whole Oat Grain Bags - Skip the prep entirely. Ready to inoculate with built-in injection ports.

Comments