How to Use a Presto 23qt Pressure Canner as a Home Autoclave for Sterilization

- Harold Evans

- Feb 25, 2025

- 4 min read

Updated: 1 day ago

For mushroom cultivators, achieving proper sterilization is essential for success. Without effective sterilization, contaminants like bacteria and mold can easily overtake your grain spawn or substrate. The Presto 23-quart pressure canner is an affordable and reliable tool that functions as a home autoclave, making it a game-changer for hobbyist and small-scale growers alike.

This guide will walk you through how to use your Presto 23qt pressure canner to sterilize grain jars and substrate blocks, ensuring a clean environment for healthy mycelium growth.

Of course, if you want to skip the 3+ hour sterilization process entirely, pre-sterilized grain bags arrive ready to inoculate. But understanding pressure canner sterilization is valuable knowledge for any serious cultivator - it gives you control and the ability to scale production on your own terms.

Why the Presto 23qt Pressure Canner?

Spacious Capacity: Holds up to 8 quart-sized jars or 4 five-pound substrate blocks.

Cost-Effective Alternative: A budget-friendly substitute for commercial autoclaves.

Versatile: Works on gas, electric, and induction cooktops (induction-ready models available).

Reliable Sterilization: Reaches 15 psi, effectively killing contaminants through high-pressure steam.

Step-by-Step Guide to Sterilizing with the Presto 23qt Pressure Canner

Step 1: Inspect the Canner

Before every use, check the rubber gasket, vent pipe, and pressure gauge for signs of wear or blockage. A faulty gasket can prevent proper sealing, leading to inconsistent pressure and incomplete sterilization. Replace damaged parts as needed.

Step 2: Add Water

Remove the lid and place the metal rack inside the canner. This prevents jars and bags from direct contact with the bottom, which could cause overheating or breakage.

Pour in 4 quarts of water to generate steam for sterilization.

Pro Tip: Elevating the rack 2 inches using foil balls, canning lids, or a taller trivet improves steam circulation and prevents jars or bags from being submerged.

Step 3: Load the Canner

Arrange jars or substrate bags on the rack, ensuring enough space for steam to circulate between them.

Avoid overloading—this can block steam flow and lead to uneven sterilization.

Using grain jar lids with proper gas exchange is critical - they must allow steam penetration during sterilization while maintaining a sterile seal afterward.

Step 4: Seal and Heat the Canner

Secure the lid, ensuring the vent pipe is clear and aligned properly.

Place the canner on your heat source (gas burner, electric coil, or induction plate).

Step 5: Vent the Steam

Turn the heat to high and wait until steam steadily escapes from the vent pipe.

Allow steam to vent for 10 minutes—this is crucial for expelling trapped air, which ensures even pressure buildup.

Step 6: Add the Pressure Regulator

Once venting is complete, place the pressure regulator (weighted gauge) onto the vent pipe.

Let the pressure build to 15 psi (pounds per square inch). Note: Trust the weighted regulator over the gauge, as dial gauges may become inaccurate over time.

When the regulator starts rocking, reduce the heat just enough to maintain gentle rocking motion—excessive rocking can cause the canner to run out of water too soon.

Step 7: Sterilization Time

Maintain 15 psi for the recommended sterilization duration:

Quart jars: 2 hours

Bags over 2 pounds: 2.5 hours

Keep an eye on the pressure to prevent fluctuations.

Step 8: Cooling Down

Turn off the heat and allow the canner to cool naturally.

Do not remove the pressure regulator or lid until the pressure lock drops—forcing it open early can be dangerous and cause contamination.

Cooling typically takes 30–45 minutes.

Step 9: Unloading and Storing Sterilized Materials

Carefully open the lid away from you to prevent steam burns.

Place jars or bags on a clean, dry towel and let them cool to room temperature before inoculation.

Do not move or shake freshly sterilized materials excessively—jars are more vulnerable to contamination when warm.

Why This Method Works

Using a pressure canner as an autoclave is a proven method for sterilizing materials in mushroom cultivation. The combination of high heat, moisture, and pressure effectively kills bacteria, mold, and spores, creating a clean growing environment for mycelium.

Steam Penetration: Pressurized steam reaches 250°F (121°C), sterilizing deep into the substrate or grain.

Air Removal: Proper venting ensures no air pockets remain, leading to uniform sterilization.

Scalability: Allows hobbyists to prepare multiple jars or bags at once, improving efficiency.

Tips for Success

Monitor Water Levels: Running out of water mid-cycle can cause overheating and ruin your materials.

Use Heat Consistently: Drastic heat fluctuations can destabilize pressure and affect sterilization.

Check for Contamination Early: If a sterilized jar shows odd colors or foul odors after cooling, discard it immediately.

Batch efficiency matters: If you're only running 1-2 jars per cycle, the time and energy investment may not justify DIY sterilization - pre-sterilized bags become cost-effective at small scales.

Don’t Overcrowd: Space out jars or bags for even steam circulation.

Final Thoughts

The Presto 23qt pressure canner is an invaluable tool for home mushroom cultivators, offering an effective and budget-friendly sterilization method. Mastering this process will greatly improve your chances of successful mushroom cultivation by eliminating contaminants before they become a problem.

By following these steps, you’re well on your way to producing clean, contaminant-free grain spawn and substrate, setting the foundation for strong mycelial growth and bountiful harvests.

Happy growing!

Master Sterilization or Skip It Entirely

The pressure canner gives you complete control over your sterilization process - essential knowledge for scaling production. But it's also a 3+ hour commitment per batch.

DIY sterilization essentials:

Premium Grain Jar Lids (6-Pack) - Autoclavable construction with reliable gas exchange

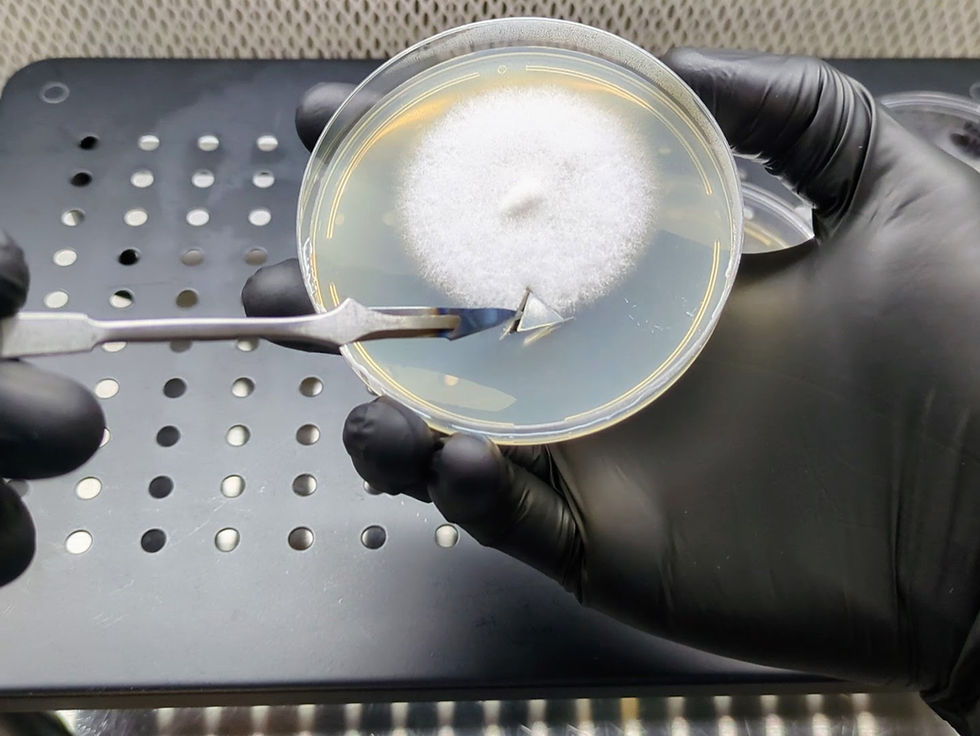

MEA Agar Plates (10-Pack) - For testing sterilization effectiveness

Or skip the prep work:

Sterilized Grain Bags (2lb) - Laboratory-sterilized, ready to inoculate

Perfect for small batches or when time matters more than cost

Both paths work - choose based on your scale, time, and goals.

Comments